Home > Products > Banana Chips Plant >

Home > Products > Banana Chips Plant >

Banana Chips Production Line|Plantain Chips Production Line|Fully Automatic Banana Chips Processing Line

- Capacity:200 sets per month

- Loading port: Qingdao Port

- Application:

- This banana chips production line is used to process fresh banana to be banana chips.

- Features

- Technical Data

- Message

- Recommended

Features

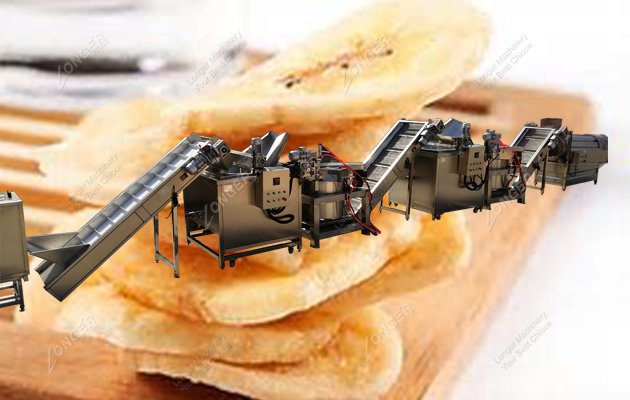

Fully Automatic Banana Chips Production Line Introduction

Fully automatic banana chips production line is according to user's feedback information was designed and developed.Plantain chips production line has the advantages of low one-time investment,low energy consumption, multiple functions, small size, high profit, and easy use and maintenance. The full set of banana chips production line consists of peeling, slicing (strips), blanching, dehydration, frying, degreasing, seasoning, packaging and auxiliary equipment.

Fully automatic banana chips production line is according to user's feedback information was designed and developed.Plantain chips production line has the advantages of low one-time investment,low energy consumption, multiple functions, small size, high profit, and easy use and maintenance. The full set of banana chips production line consists of peeling, slicing (strips), blanching, dehydration, frying, degreasing, seasoning, packaging and auxiliary equipment.

Features of Plantain Chips Production Line

1.Plantain chips production line is made of high quality stainless steel,reach to health standard,the machines of banana chips production line is easy to clean.

2.The frying machine keeps the frying oil clean, thus reducing oil consumption and improves banana chips quality.

3.This banana chips production line is with high working efficiency, could save the labor and energy.

4.Our plantain chips making machine was equipped with advanced and efficient heating system, which could avoid the energy waste.

5.Our banana chips processing line has the superior quality and competitive price.

Suitable for large scale banana chips production.

Working Procedure of Banana Chips Production Line

Banana Chips Production Line Working Flow:

Plantain---Cutting to be slice---rinsing---blanching to protect the color---de-watering to remove the water on the surface of plantain chips---fryer machine---de-oiling to remove the oil on the surface of plantain chips---seasoning machine to add different flavor on the plantain chips---packing.

Working Procedure of Banana Chips Production Line

1. Peeling the banana, this first step needs to peel the banana by labor, because now no such machine to peel the banana.

2. Banana Cutting Machine. Use this banana cutting machine to cut the banana into round chips.

3. Banana Chips Blanching Machine. Blanch banana chips with boiled water, thus making banana chips easier for frying.

4. Banana Chips De-watering Machine. After blanching, it need to remove the water on the banana chips, because the blanched banana chips contain too much water, fry it directly will be very dangerous.

5. Banana Frying Machine. Use frying machine to fry the banana chips and cook them.

6. Banana De-oiling Machine. After frying, there is extra oil on the banana chips, which makes the chips oily, removing extra oil will make banana chips crispy and more delicious.

7. Banana Flavoring Machine. Use flavoring machine to season the banana chips by adding flavorings to the chips.

8. Banana Chips Packing Machine. Use packaging machine to pack banana chips into plastic bags. This packing machine is an automatic one, it can shape up the bags, weight the chips, fill the chips into bags, and seal the bags.

Fully Automatic Banana Chips Production Line Market advantage:

1. Material: Banana chips production line of our company is made of stainless steel,chooses stainless steel is absolutely up to national standard, conform to the food grade stainless steel material.

2. Performance: Fried banana chips production line is easy to operate, really realizing the automatic operation and high efficiency, saving labor and energy, covers small area.

3. Fried banana chips production line is easy to maintain,let you no worries when using this production line.

Technical Data

| Item | Power | Size |

| 1.Plantain Chips Cutting Machine(3 sets) | 0.75kw 380V-3/220V-3 | 650*550*900mm |

| 2. Rinsing Machine | 5kw/380v/50Hz | 4000*1600*900mm |

| 3. Blanching Machine | 70kw/380v/50Hz | 4000*1600*950mm |

| 4. Vibrating De-oiling Machine | 1.5kw/380v/50Hz | 1800*1000*900mm |

| 5. Air De-watering Machine | 15kw/380v/50Hz | 4000*1200*1400mm |

| 6. Elevator | 0.75kw/380v/50hz | 1500*800*1300mm |

| 7. Electric Heating Fryer Machine | 203kw/380v/50Hz | 5000*1200*2600mm |

| 8. Vibrating De-oiling Machine | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| 9. Air Drying Machine | 8kw/380v/50Hz | 4000*1200*1600mm |

| 10. Elevator | 0.75kw/380v/50Hz | 2000*800*2200mm |

| 11. Seasoning Machine | 1.5kw/380v/50hz | 2000*700*1600mm |

| 12.Automatic Packing Machine | 4kw/380v/50hz | 3000*3000*2800mm |

Message

Related Products