Home > Products > Potato Chips Plant >

Home > Products > Potato Chips Plant >

Potato Chips Production Line|Automatic Potato Chips Processing Line|Commercial Potato Chips Making Line

- Capacity:100-1500 kg/h

- Loading port: Qingdao Port

- Application:

- These potato chips making machines are mainly used to make potato chips with fresh potato.

- Features

- Technical Data

- Message

- Recommended

Features

Automatic Potato Chips Production Line Introduction

The potato chips are one kind of snack processed from fresh potatoes. After washing,peeling, slicing, frying and flavoring.The potato chips remains the special delicious flavor of roasted potato and has the characteristics of rich nutrition, delicious, convenient on the other and thus won the favor of the consumer,the potato chips production line becomes more and more popular.

The potato chips are one kind of snack processed from fresh potatoes. After washing,peeling, slicing, frying and flavoring.The potato chips remains the special delicious flavor of roasted potato and has the characteristics of rich nutrition, delicious, convenient on the other and thus won the favor of the consumer,the potato chips production line becomes more and more popular.

Features of Potato Chips Production Line:

1.The potato chips making machines are made of Stainless Steel 304.

2.For finished product, its capacity is 300kg/h.

3.All bearings are stainless steel bearings, electric are made of Chint Brand or Schneider Brand.

Automatic Potato Chips Production Line Equipment:

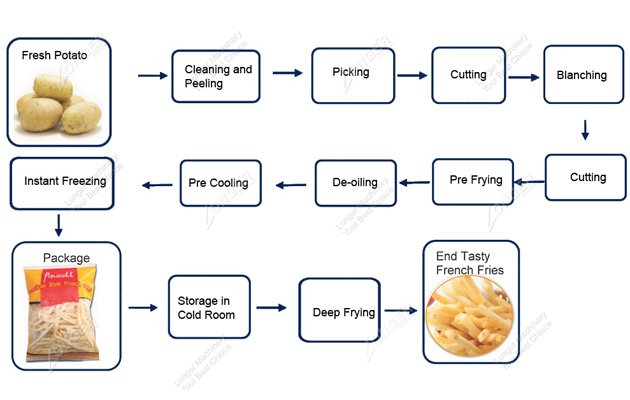

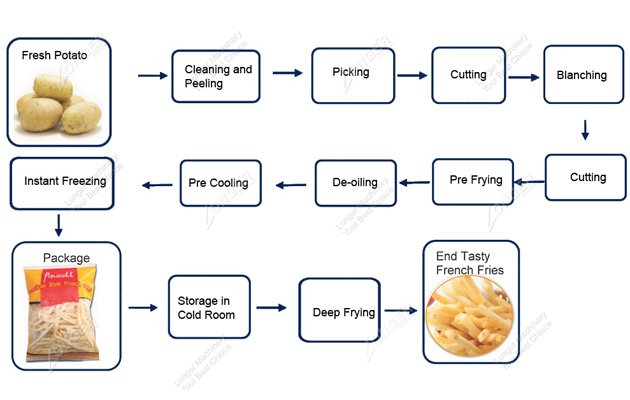

Process for the production of fried potato chips and chips:

lifting feed→clean peeling→chopping pruning→increasing feeding→slicing (bars)→rinsing→blanching hot protection→dehydration→fried→deoiling→flavoring→conveying → Packaging.

lifting feed→clean peeling→chopping pruning→increasing feeding→slicing (bars)→rinsing→blanching hot protection→dehydration→fried→deoiling→flavoring→conveying → Packaging.

The potato chips production line equipment adjustment process can produce fried French fries.

1.Potato washing and peeling machine: The use of gold steel sand lining cleaning peeling machine or brush cleaning washing machine can complete the cleaning and peeling work at the same time. High efficiency and low loss.

2.Potato slicer cutting machine: both slice and cut. Slice thickness, cutting size can be adjusted.

3.Potato chips blanching machine: rinse and protect the cut potato chips.

4.Potato chips dewater machine: Dewatering with centrifugal force. Dehydration before frying can greatly shorten the frying time and improve the taste of potato chips. Improve production efficiency and reduce production costs.

5.Potato chips continuous frying machine: This potato chips continuous frying machine is the most advanced frying equipment. Due to different proportions of water and oil, the water is on the lower side, and the oil is heated to make potato chips in the upper layer. The resulting residue is directly precipitated in the water. The oil does not emit black smoke, which greatly prolongs the service life of the oil and results in a significant cost reduction. The precise control of the oil temperature guarantees the quality and taste of the potato chips. After the work is completed, the water is released and the residue flows out with the water.

6.Potato chips deoiler: Centrifugal deoiler will deoil the freshly fried potato chips (bars) to overcome the defects of high oil content and greasy mouthfeel. Improves the taste of chips (bars).

7.Automatic potato chips seasoning machine: The drum type seasoning machine is made of stainless steel. The potato chips (strips) are uniformly turned during the rotation of the drum and the seasoning is sprayed or sprayed. Seasoning evenly and unbreakable.

8.Nitrogen filling packaging machine: When packaging, in the packaging bag filled with nitrogen, can effectively prevent the potato chips (strip) crushed, extend the shelf life. Inflate, pack, and code one time.

After Sale Service

After Sale Service

1.After the potato chips equipment is installed, conduct free instruction training for the operator designated by your company so that it can master the operation method of the equipment and perform general maintenance.

2.One-year free warranty is provided for the product from the date of acceptance of the equipment and delivered to the product. (Including natural damage to parts and components, except for electrical components. If any damage is caused by improper operation of your company's personnel, only the appropriate amount will be collected after negotiation. material fee). After the warranty period expires, our company will provide a permanent warranty on the product and will only charge the appropriate cost and waive the labor cost.

3.To ensure that your company's equipment achieves the best operating results, and also to save our company's maintenance costs, it is ensured during the warranty period that professional technicians are regularly assigned to conduct inspections and maintenance on the products.

4.When the equipment fails, we receive your notice, to help you solve the problem as soon as possible to ensure the normal operation of the equipment.

Technical Data

| Item | Power | Dimension |

| 1. Elevator | 0.75kw/380v/50Hz | 2000*800*1600mm |

| 2. Cleaning and Peeling Machine | 4.75kw/380v/50Hz | 3100*900*1500mm |

| 3. Sorting Conveyor | 0.75kw/380v/50Hz | 3000*900*900mm |

| 4. Potato Chips Cutting Machine | 1.1kw/380v/50Hz | 950*800*950mm |

| 5. Rinsing Machine | 5kw/380v/50Hz | 5000*1600*900mm |

| 6. Blanching Machine | 70kw/380v/50Hz | 6000*1600*950mm |

| 7. Air De-water Machine | 15kw/380v/50Hz | 4000*1200*1400mm |

| 8. Elevator | 0.75kw/380v/50hz | 1500*800*1300mm |

| 9. Electric Heating Potato Chips Fryer Machine | 203kw/380v/50Hz | 7000*1200*2600mm |

| 10. Oil Filter Machine | 1.5kw/380V | 1100*600*950mm |

| 11. Vibrating De-oil Machine | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| 12. Air Drying Machine | 8kw/380v/50Hz | 4000*1200*1600mm |

| 13. Elevator | 0.75kw/380v/50Hz | 2000*800*2200mm |

| 14. Flavoring Machine | 1.5kw/380v/50hz | 2400*1000*1600mm |

Message

Related Products